Belt, Monorail, Roller

The Continuous Belt Conveyor Blast Machine is ideal for symmetric, sensitive work pieces. Our Roller Conveyor Blast Machines are the right solution for heavy plates and structural shapes. Lastly, our Monorail Conveyor Blast Machines are preferred by customers who are blasting heavy work pieces at a high pass through rate.

The Pangborn Vertical Descaling Systems provide high volume production and cost effective performance for deburring, cleaning, descaling, or etching of plate, structurals and fabrications. Customized work handling solutions (monorail, crane, and roll conveyors) allow for maximum flexibility. Pangborn Combination Descaling Systems maximize the cleaning of smaller products by providing high volume production and cost effective performance for deburring, cleaning, descaling, deflashing or etching. It is extremely versatile for efficient blast coverage.

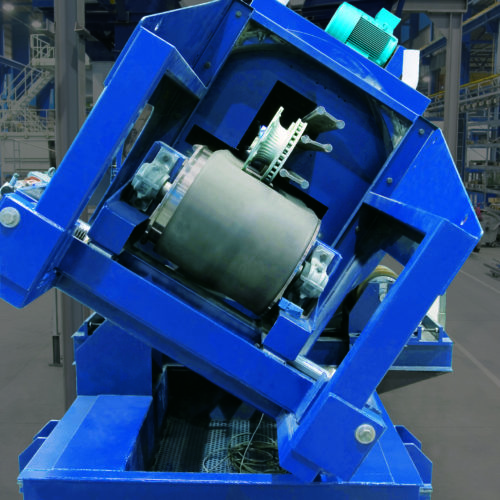

Featuring an endless belt conveyor, the Pangborn Continuous Belt Conveyor Blast Machine is ideal for rotation-symmetric shock and vibration sensitive work pieces (brake drums, brake discs, wheel rims, etc.). Work pieces are blast cleaned in a continuous flow and in a reliable, cost effective manner. The machine body is inclined in the flow and transverse direction, and the blast wheels are installed on the two longitudinal directions and cover section sides. The transverse inclination is adjustable depending on the work pieces to be blast cleaned.

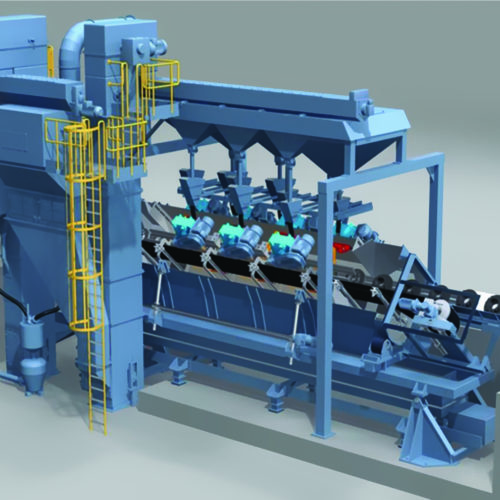

Pangborn’s Monorail Conveyor Blast Machines are usually recommended for use in situations that require blasting heavier work pieces at a high rate. These machines are exceptionally configurable and use as many as 24 blast wheels for outstanding speed without sacrificing coverage. Because of the overhead conveyor system, these machines are perfect for moving heavier work pieces through the blast chamber, and depending on the work and speed required, a monorail, “power & free”, or self-driving trolley may be employed. Our Monorail Conveyor Blast Machines are all constructed to meet heavy duty applications and use extremely durable special alloy liners for increased longevity.

Depending on the customer’s requirements, several solutions are available including those with special and wear resistant hooks.

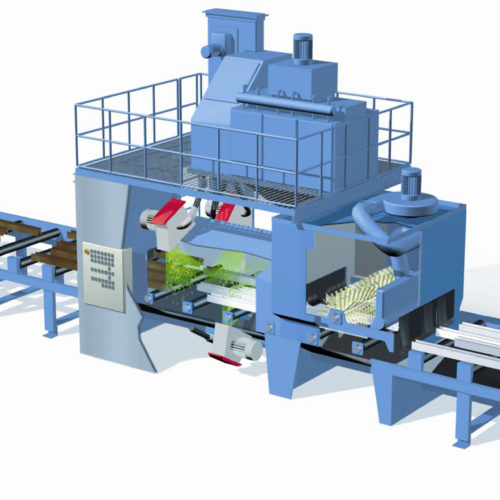

The use of Pangborn’s Roller Conveyor Blast Machine system for descaling is a cost-effective means of reducing today’s high manufacturing expenses while improving the quality of work.

A clean, rust, and scale-free surface is a fundamental requirement for the anti-corrosion treatment of rolled steel products (sheet metal plates, rolled sections, tubes, and simple structural steel work). Because several plate and structural shapes are often extremely heavy and large, a roller conveyor machine is usually the only method used to safely and thoroughly clean these types of work pieces.

Steel descaled by a Pangborn Roller Conveyor Blast Machine can lengthen tool and die life, improve burning, welding, and machining operations; and, provide the proper surface finish for the application of modern exotic coatings.

Pangborn descaling systems are available for a wide variety of steel products — plates, sheets, strips, wires, bars, billets, slabs, rolled and fabricated structural shapes, and miscellaneous weldments, pipe, tubing, and gas cylinders. Our systems are capable of being equipped with customer specific loading and unloading units. In addition, these systems can be used as single machines or integrated into descaling and anti-corrosion treatment lines.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn Conveyor Blast Machines are a diverse line of machines designed to provide faster throughput and maximum blast coverage for a continuous flow of work pieces.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2024 Pangborn. All Rights Reserved. Privacy Policy