In harsh blast conditions, a two percent (2%) volume of sands/fines in the abrasive can reduce the wear life of the internal wheel components by as much as 50%.

Abrasive recovery and waste stream management are one of the most important aspects of your shot blasting system. The right solution can improve the following:

Pangborn offers a complete line of abrasive recovery and waste stream solutions to meet any shot blast application. We work closely with our customers to understand their abrasive recovery expectations and how they intend to manage their end-of-life waste stream. A Pangborn solution can be incorporated into the design of new equipment, retrofitted on existing blast equipment (from Pangborn or a competitor), or delivered as a stand-alone system.

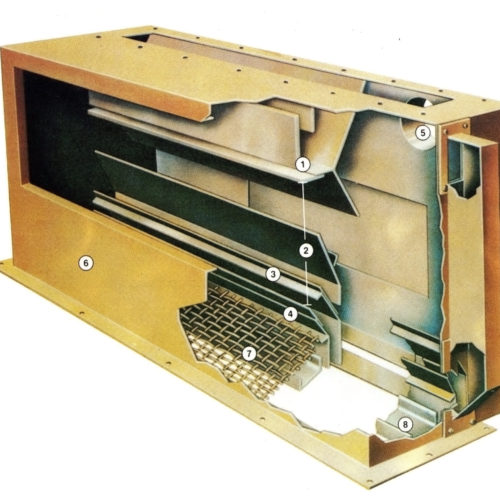

One of the most expensive consumables with any wheel blast system is the abrasive used in a blast operation. One of the best ways to extend the life of abrasive is to use an effective abrasive separator. A faulty abrasive separator can bring blast operations to a grinding halt and result in costly repairs if dust and debris enters the blast wheel.

Pangborn has a number of solutions easily adaptable to any manufacturer’s blast equipment. Our systems enable our customers to more efficiently recycle shot by removing dust and debris out of the blast stream.

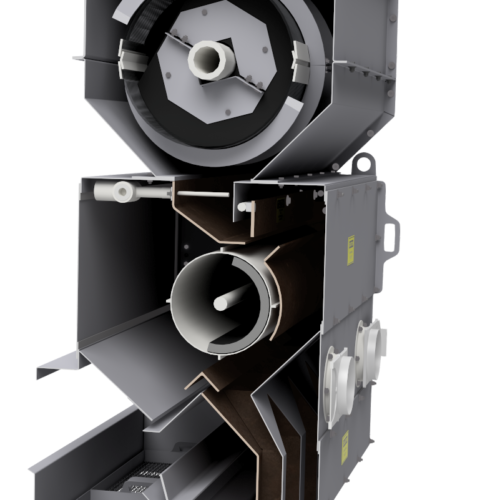

Abrasive Separator Features & Benefits

Pangborn may recommend either an airwash or magnetic separator with airwash depending on your specific operation and the type of abrasive being used.

Learn more about Pangborn’s blast cleaning and shot peening equipment solutions.

When large quantities of sand are generated during blasting, an especially effective and environmentally responsible abrasive sand separation system is required.

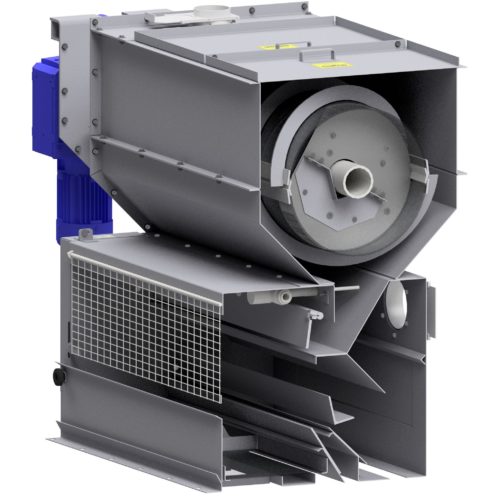

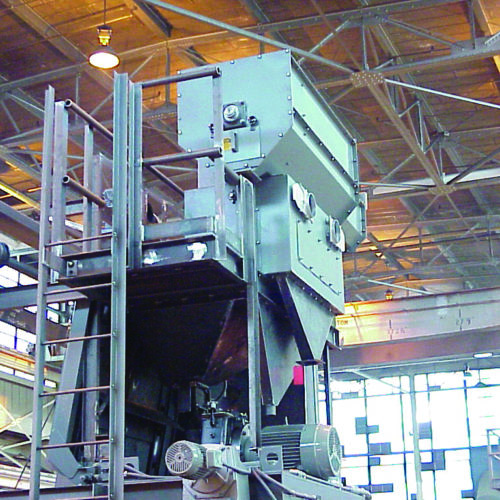

Pangborn’s magnetic separators are proven effective in extreme conditions in the foundry industry. The system can be retrofitted to existing blast machines for output enhancement.

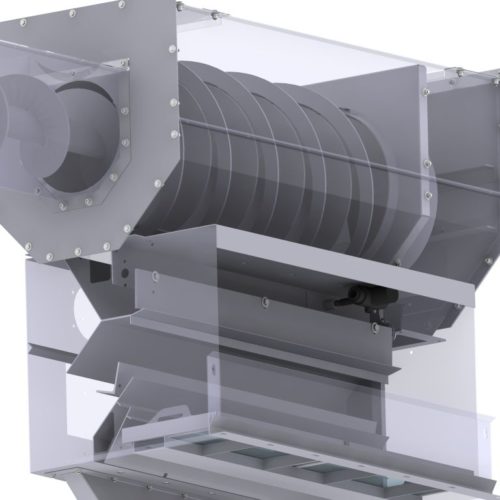

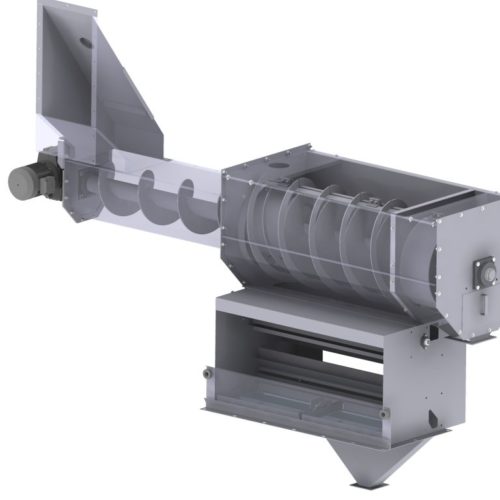

Pangborn’s RotoConditioner III Mechanical Scrubber is designed to cut your new sand usage by up to 90% while substantially reducing your operating and maintenance costs. It quickly removes surface clay and binder residues (organic and inorganic) from sand grains and improves sand geometry.

Compared to competitive scrubbers (pneumatic, wet or thermal), the RotoConditioner III requires less horsepower, takes up less floor space, and is generally less costly to install.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2024 Pangborn. All Rights Reserved. Privacy Policy